Page 20 - PDF_Flip_Book

P. 20

Rod Machado’s Private/Commercial Pilot Handbook

5-42

which alters the position of (precesses) that gyro (no, there’s no gyro in the

HSIs found in most airplanes). As a result, the remotely located directional

gyro is kept aligned to the airplane’s current magnetic heading. The informa-

tion from the remotely located directional gyro and flux valve is then sent to the

HSI. Small motors in the HSI unit turn its vertical compass card to provide the

airplane’s correct magnetic heading. This process is called slaving, and it’s

what’s being referred to when someone speaks of a slaved gyro (and no, you

don’t need to try and free all the world’s slaved

gyros, either).

The other component is a slaving meter-com-

pensator unit (Figure 85). The slaving meter tells

you when there’s a difference between the air-

plane’s actual magnetic heading and the heading

displayed on the heading indicator. In the event an

error between these two readings exist, the pilot

could use the slaving meter to temporarily correct it

Fig. 84 before having the unit checked or repaired. Fig. 85

Postflight Briefing #5-4

Three Ring Laser Gyro

To provide pitch and bank information, an attitude and heading

reference system (AHRS) typically uses three laser gyros, one for

each airplane axis (Figure 86). Computer assessment of all these

three gyros (along with other components of the AHRS) provides

the basic heading and attitude reference along with present posi-

tion, groundspeed, drift angle and attitude rate information. The

onboard computer begins assessing this information once it has

been initialized by determining the initial vertical position and

heading.

The ring laser gyro uses laser light to measure angular rota-

tion. Each gyro (one for each airplane axis) is a triangular-

shaped, helium-neon laser that produces two light beams, one

traveling in the clockwise direction and one in the counterclock-

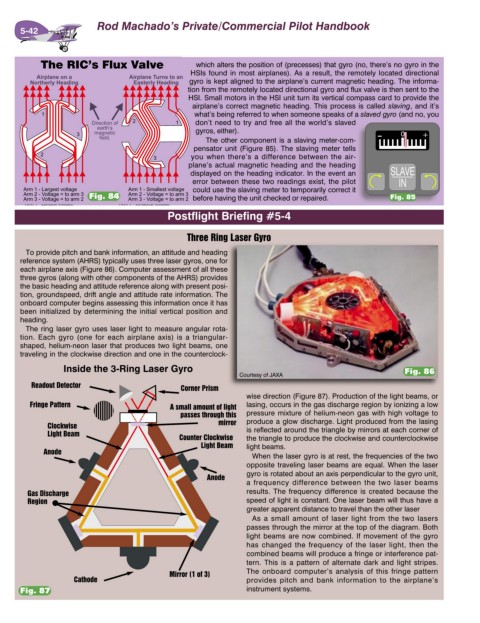

Inside the 3-Ring Laser Gyro Fig. 86

Courtesy of JAXA

Readout Detector Corner Prism

wise direction (Figure 87). Production of the light beams, or

Fringe Pattern A small amount of light lasing, occurs in the gas discharge region by ionizing a low

passes through this pressure mixture of helium-neon gas with high voltage to

Clockwise mirror produce a glow discharge. Light produced from the lasing

is reflected around the triangle by mirrors at each corner of

Light Beam

Counter Clockwise the triangle to produce the clockwise and counterclockwise

Light Beam light beams.

Anode

When the laser gyro is at rest, the frequencies of the two

opposite traveling laser beams are equal. When the laser

gyro is rotated about an axis perpendicular to the gyro unit,

Anode

a frequency difference between the two laser beams

Gas Discharge results. The frequency difference is created because the

Region speed of light is constant. One laser beam will thus have a

greater apparent distance to travel than the other laser

As a small amount of laser light from the two lasers

passes through the mirror at the top of the diagram. Both

light beams are now combined. If movement of the gyro

has changed the frequency of the laser light, then the

combined beams will produce a fringe or interference pat-

tern. This is a pattern of alternate dark and light stripes.

Mirror (1 of 3) The onboard computer’s analysis of this fringe pattern

Cathode provides pitch and bank information to the airplane’s

Fig. 87 instrument systems.