Page 4 - PDF-Sample

P. 4

Chapter-1 Getting Ready to Fly-V20_Sport Pilot Handbook 8/30/2021 5:42 PM Page 25

Chapter 1: Let’s Go Flying 1-25

Draining the fuel sump located just prior to the fuel pump

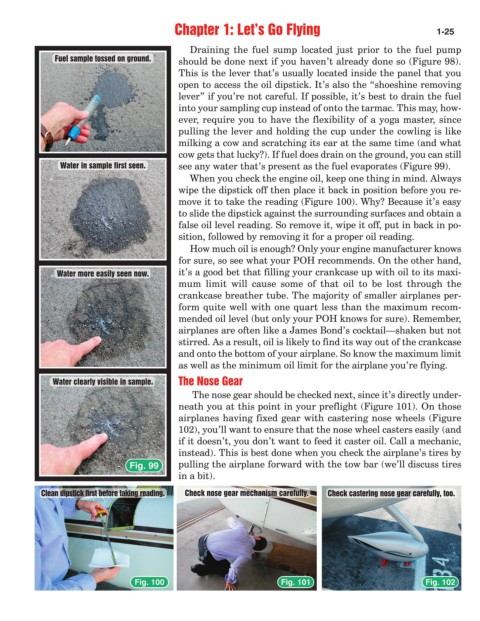

Fuel sample tossed on ground. should be done next if you haven’t already done so (Figure 98).

This is the lever that’s usually located inside the panel that you

open to access the oil dipstick. It’s also the “shoeshine removing

lever” if you’re not careful. If possible, it’s best to drain the fuel

into your sampling cup instead of onto the tarmac. This may, how-

ever, require you to have the flexibility of a yoga master, since

pulling the lever and holding the cup under the cowling is like

milking a cow and scratching its ear at the same time (and what

cow gets that lucky?). If fuel does drain on the ground, you can still

Water in sample first seen. see any water that’s present as the fuel evaporates (Figure 99).

When you check the engine oil, keep one thing in mind. Always

wipe the dipstick off then place it back in position before you re-

move it to take the reading (Figure 100). Why? Because it’s easy

to slide the dipstick against the surrounding surfaces and obtain a

false oil level reading. So remove it, wipe it off, put in back in po-

sition, followed by removing it for a proper oil reading.

How much oil is enough? Only your engine manufacturer knows

for sure, so see what your POH recommends. On the other hand,

Water more easily seen now. it’s a good bet that filling your crankcase up with oil to its maxi-

mum limit will cause some of that oil to be lost through the

crankcase breather tube. The majority of smaller airplanes per-

form quite well with one quart less than the maximum recom-

mended oil level (but only your POH knows for sure). Remember,

airplanes are often like a James Bond’s cocktail—shaken but not

stirred. As a result, oil is likely to find its way out of the crankcase

and onto the bottom of your airplane. So know the maximum limit

as well as the minimum oil limit for the airplane you’re flying.

Water clearly visible in sample. The Nose Gear

The nose gear should be checked next, since it’s directly under-

neath you at this point in your preflight (Figure 101). On those

airplanes having fixed gear with castering nose wheels (Figure

102), you’ll want to ensure that the nose wheel casters easily (and

if it doesn’t, you don’t want to feed it caster oil. Call a mechanic,

instead). This is best done when you check the airplane’s tires by

Fig. 99 pulling the airplane forward with the tow bar (we’ll discuss tires

in a bit).

Clean dipstick first before taking reading. Check nose gear mechanism carefully. Check castering nose gear carefully, too.

Fig. 100 Fig. 101 Fig. 102